Photometry Lab

- The in-house photometry lab ensures that all our products are designed to deliver the most soothing light, and optimum illumination levels for all kinds of applications.

- We measure various photometric parameters to ensure that we provide superior “quality of light” to the customer, in order to help enhance working environment and productivity.

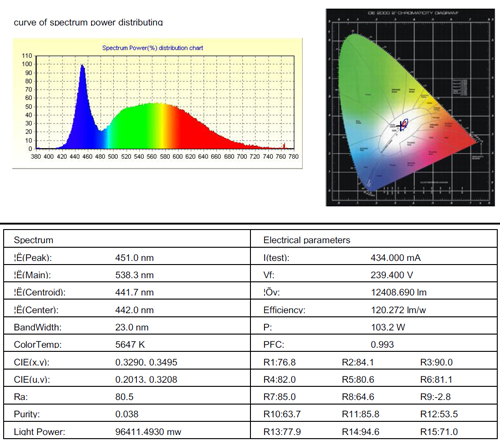

- Color Rendering Index ( CRI ) : It is the ability of the LED lamp to accurately reveal the true colors of objects in comparison with natural sunlight. High CRI of Eetamax products ensures that the user experiences vivid colors in their true form.

- Correlated Color Temperature ( CCT ) : It is the “appearance” of the light emitted by white LED. Light may be “Warm White”, “Neutral White”, or “Cool White” and can range from 2700 K to 6500 K. Eetamax products are available in variety of CCT requirements and can be customized as per customer requirements.

- Total Luminous Flux : It is the total amount of visible light emitted by the lamp. It is measured in Lumens.

- Light efficacy ( Lumens per Watt ) : Lamp efficacy is the ideal conditions light output per watt of the LED lamp. System efficacy is the practical light output per watt of the entire fixture. System efficacy is usually lower than lamp efficacy. Eetamax always strives to provide highest system efficacy to the customers.

Thermal Lab

- Temperature Controlled Oven : All Eetamax products are tested as per the supremely rigorous full-switching 1000 cyclic operations test at elevated temperatures. Only the best quality products that perform within rated parameters even in these worst conditions are accepted and standardized for production.

- Junction Temperature Test: The performance of an Light Emitting Diode (LED) depends greatly on the temperature at which it’s P-N junction is made to operate. Although today’s LEDs are rated for operation even above 100℃, the lamp’s lumen efficacy, lumen depreciation, CCT maintenance, and overall life are all better at lower temperatures. Eetamax products are designed such that they operate at @20℃ lower than similar competitor products for same ambient temperature.

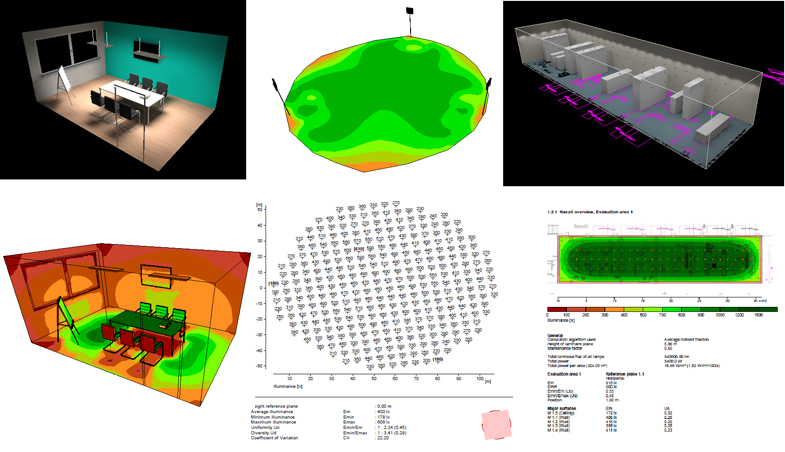

Basic purpose of lighting designing is to prepare uniform light distribution in particular areas. Luminance distribution within a field of vision is an extremely important criterion in lighting design.

The lighting level produced by a lighting installation is usually qualified by the illuminance produced on a specified plane. In most cases , this plane is a major plane of the task in the interior and is commonly called as working plane.

The five steps of lighting design as we follow :

- Determine lighting requirement

- Select Lamp ,luminaires and lighting management

- Calculate Number of luminaires required

- Position Luminaires and lighting control

- Analyse the result

By using above steps we provide detail lighting layout report to the customer, With reference to these lighting layout, Lighting installation will be done.

Automated Pick & Place Machine

- Fully automated handling of LED chips during assembly on the PCB avoids possible damage to the delicate LED by manual handling.

- Automated machinery increases speed and accuracy, and ensures consistency in quality.

Five Zone Reflow Oven

- Instead of the popular three zone reflow oven, Eetamax products are manufactured in the higher grade five zone automated reflow oven. The gradual rise in temperature ensures that the LED is soldered perfectly, and a high quality joint for long life is produced.

- Soldering pastes used in all Eetamax products are ROHS international standard compliant to remain environment friendly.

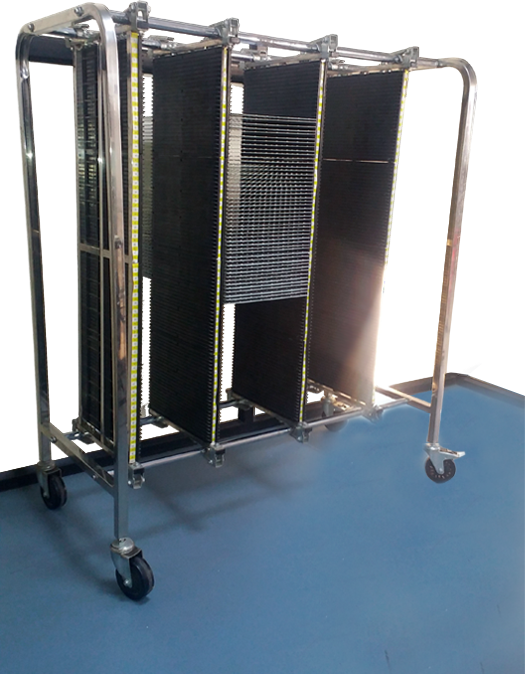

Anti-Static Zones for LED assembly

- Electrostatic discharge ( ESD ) protected zones are created in all areas where LED are to be assembled.

- This ensures that stray static charges do not harm the electronic diodes in the LED chips, and ensures good performance and reliability.

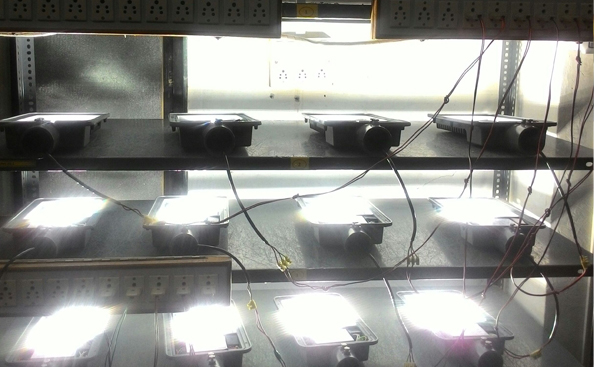

Fixture Soak Test

- The soaking test is performed over 100% products of Eetamax for a fix time of 2 to 6 hours. This test ensures the preliminary reliability & product performance.

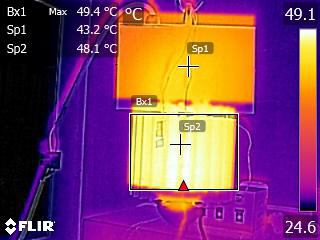

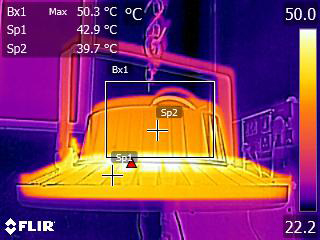

- Thermal imagery is done to ensure further reliability after soaking test is done.

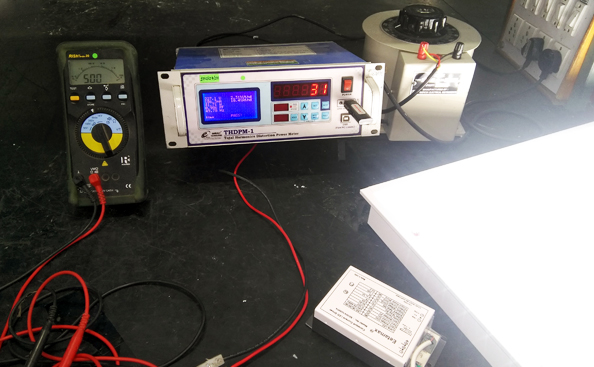

Power Analysis / THDPM

- 100% of Eetamax products are tested for its rated electrical parameters like Power, Voltage, Current, Power Factor, and Total Harmonic Distortion.

- The measurement of the electrical parameters is done with the help of Power Analyzer which provides precise measurements. These test results are traceable to individual fixture after QC and subsequent sale.

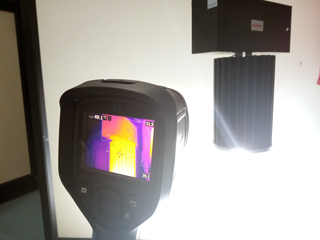

Thermal Imager

- Eetamax products are designed for superior thermal management & high grade performance over the entire product life.

- Eetamax uses highly proficient thermal imager which provides an all-in-one, undiluted thermal picture with visible light features which lets us instantly recognize problematic heat patterns for advanced inspection and troubleshooting.

- LED being a semiconductor, its life and efficiency depend heavily on the performance of the heatsink. The depreciation in the light output of lamps over the years is typically because of poor thermal management.

Insulation Test

- All electrical components and end product comply with insulation resistance specifications so that they can operate safely.

- 100% of Eetamax fixtures are tested for Insulation Resistance to ensure end user’s safety.

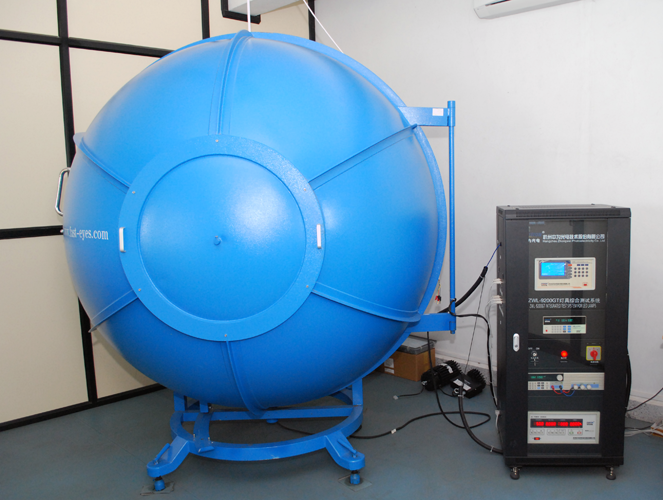

Photometry Test

- To ensure that our products consistently deliver not just the same quantity but also same quality of light, our products are sample tested for all their photometric parameters such as CRI, CCT, Total Luminous Flux, Lumens per Watt, etc.